EUropean LOw Speed Aircraft Model at high Reynolds II

(Companies involved in the consortium: NHOE Srl, IBK-INNOVATION GMBH & CO. KG, ILM Srl,)

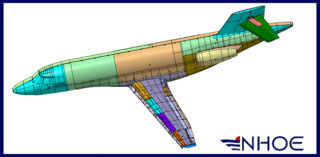

In laminar flow investigations, several parameters related to manufacturing quality of the aircraft wind tunnel model have to be taken into account since they can strongly affect the laminar-turbulent transition location. Model shape, steps and gaps, waviness and surface roughness of the model, are key parameters for the quality of laminar flow investigation. Even if this effect is not so amply described in literature where few empirical and inaccurate correlations between the roughness height and the transition position can be found, experimental results have shown that distributed roughness strongly affects the laminar-turbulent transition. This phenomenon can be managed through a very good mechanical design able to avoid possible step and gap coming from the integration of different parts composing the model and taking care, in the manufacturing phase, of the waviness and of the surface refinement, both being challenging tasks. Last, but not least, the number of pressure sensors and their integration in the leading region (necessary to correctly capture the stagnation region) requires special and innovative solutions to avoid laminar flow contamination. Fully in line with JTI-CS2-2017-CfP07-AIR-01-30, the overall objective of the project is to support the development and assessment of natural laminar aircraft integrating innovative aerodynamic control surfaces, and High lift technologies. The EULOSAM II project focuses on the modification and completion of a WT-model that allows analysing of the aerodynamic performance of innovative control surfaces and high-lift devices. Model main size is roughly 2.25 m in span for an area of around 1.2 m^2 with a the Horizontal Tail Plane (HTP) of 0.8 m in span for an area of 0.26 m^2.

For more details please refer to CORDIS EU research results website.